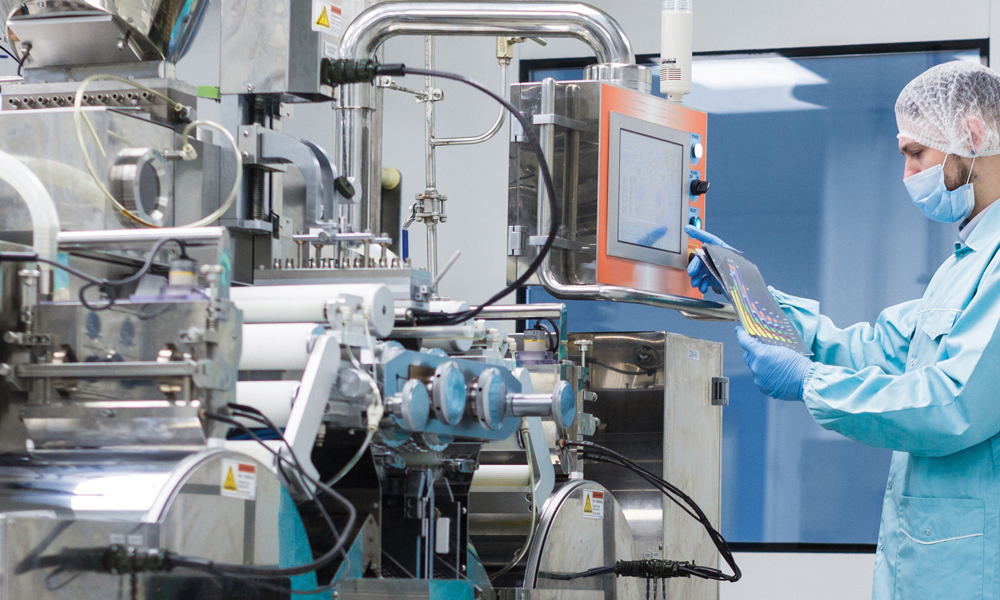

GMP (Good Manufacturing Practices) is a set of guidelines that manufacturers must follow to ensure their products meet high-quality standards. Understanding and maximizing today’s technologies can strengthen your organization’s compliance with these regulations.

Energy efficiency is vital to ensuring your company complies with GMP regulations. However, many pharma companies need help to achieve energy efficiency goals because they need help with work.

Automate as much of the process as possible

Good Manufacturing Practices or GMP guidelines ensure that products like pharmaceuticals, food, and cosmetics meet set quality standards. These guidelines help businesses for GMP manufacturing projects avoid costly mistakes such as product recalls, fines, or even employee jail time. It also helps them increase consumer trust and brand reputation.

The main requirement of the GMP system is to have a documented set of procedures for undertaking each critical step of production. These procedures should be explained in detail and followed consistently, regardless of who is carrying out the process at a given time. They should also be tested for usability by a third party to ensure they are clear and logical.

It is also essential to keep accurate records of each stage of the production process, including raw materials, equipment, and finished drugs. These records can be used to prove that the procedures were carried out correctly and that a quality drug was produced. This is vital during an audit and can help reduce non-compliance risk.

It is also necessary to have a well-trained staff to carry out the procedures in a compliant manner. Employees should be able to understand the written policies and receive initial and ongoing training relevant to their job responsibilities. Additionally, it is essential to record the specific duties of each worker to avoid overlapping responsibilities.

Create a transparent workflow.

GMP guidelines ensure that pharmaceuticals, medical devices, and food are produced safely and consistently by their set quality standards. This helps minimize the risks of errors, contamination, and mix-ups during production and distribution. It also helps to protect consumers from substandard products.

Aside from ensuring that all equipment adheres to pre-determined conditions, it’s essential to have transparent workflows and procedures in place. This entails defining precise roles and duties for each stage of the production process. It’s also necessary to provide ongoing training for all employees. This helps ensure all employees thoroughly understand their responsibilities and the importance of complying with GMP standards.

Creating a strong culture of compliance is crucial to achieving and maintaining GMP compliance. A good culture of compliance involves encouraging employees to report any violations or deviations from established protocols. It also involves creating a system for investigating any significant variations.

One way to improve your culture of compliance is to invest in a sophisticated QMS software solution. This can help you create a more effective quality management system that complies with all of the requirements of GMP, including providing transparent workflows and training for your employees. It can also help you keep track of all your manufacturing activities, including preparing batch records and test methods.

Invest in quality control software.

A good quality control software solution will make life as a GMP manufacturer much easier. It will improve the speed of inspections, audits, and investigations, making them more effective and accurate. Plus, it can help you avoid consumer incidents that could damage your brand and bottom line.

Investing in a quality management system (QMS) can be a significant expense, but it will provide a great return on investment (ROI). The right software will help you save time and money by automating the manual collection process and reporting quality data. Moreover, it will enable you to make better decisions with real-time analytics that eliminate bias and allow a greater understanding of quality metrics.

As an added benefit, investing in high-quality software will reduce the risk of costly product recalls and regulatory fines. Additionally, this will enhance the entire consumer experience and brand perception.

The best GMP manufacturing software will allow you to quickly and easily identify areas of improvement by analyzing your current processes. It will also help you implement best practices by highlighting gaps that must be closed. A quality software solution will also handle multi-user access, making sharing and updating information with other teams in the organization easier. This will be especially important in highly regulated pharmaceuticals and medical devices industries.

Train your employees

Observing GMP guidelines ensures that your products meet strict quality standards. It guards against poor hygiene, temperature control, cross-contamination, and adulteration of raw materials or final products that can lead to adverse health effects for consumers. This is why it’s so important to have a quality team that is well-trained in all aspects of manufacturing operations, including sanitation, recordkeeping, and equipment handling.

Sophisticated quality management software can make it easier for your team to adhere to these standards. Digital SOPs (standard operating procedures) reduce the likelihood of errors by ensuring that all steps are clearly defined. They can also be reviewed and approved by an outside third party. Using a quality inspection app can further streamline your processes by providing the tools you need to perform mobile inspections on-site or remotely. This includes reviews for restaurants, construction sites, food safety audits, and more.

In addition to training, a quality team should be responsible for performing scheduled operations assessments. This way, problems can be identified early on, and preventative measures can be taken. A quality assessment should include a review of processes and activities and an evaluation of current levels of compliance. It should also take into account any deviations from standard procedures that are causing the most concern. It should also consider the overall data governance system.